Curing Adhesives Market: Advancing Manufacturing with High-Performance Bonding Solutions

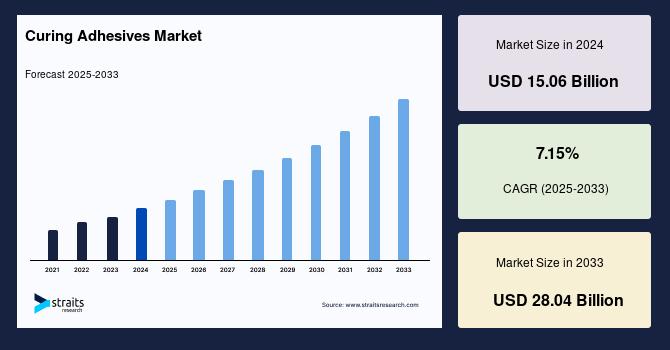

The global Curing Adhesives Market Size was valued at USD 15.06 billion in 2024 and is projected to reach from USD 16.14 billion in 2025 to USD 28.04 billion by 2033, growing at a CAGR of 7.15% during the forecast period (2025-2033). This upward trajectory reflects curing adhesives’ critical role in delivering durable, lightweight, and chemically resistant bonds across various sectors including electronics, automotive, construction, and aerospace.

Understanding Curing Adhesives and Their Significance

Curing adhesives undergo a chemical process that transforms them from liquid or thermoplastic states into fully crystallized, solid forms. This reaction endows the adhesives with their ultimate strength, enabling them to offer bond lines that range from flexible to rigid. The ability to withstand harsh environmental factors such as temperature fluctuations and chemical exposure makes curing adhesives ideal substitutes for traditional bonding techniques like mechanical fastening and soldering.

The growing complexity and miniaturization of electronic devices have increased the reliance on curing adhesives in manufacturing. They facilitate high-production yields with minimal handling and damage risk, supporting processes such as wire and part tacking, structural bonding, encapsulation, potting, and conformal coating. Compared to conventional soldering, curing adhesives enable more efficient in-line testing and assembly, helping electronics manufacturers meet environmental, health, and safety standards while reducing costs.

Market Drivers Across Key Industries

Electronics and Electrical

The electronics sector is the largest contributor to the curing adhesives market. The upward trend of miniaturization, embedded technologies, and advanced electronics demands adhesives with precise bonding performance and reliable long-term durability. Curing adhesives help replace traditional soldering in components like smartphones, digital cameras, computers, medical devices, and telecommunications hardware, thus accelerating production rates while lowering operational costs.

Automotive Industry

A prominent market driver is the automotive industry, which increasingly necessitates lightweight, high-strength materials to enhance fuel efficiency and reduce emissions. Curing adhesives are essential in automotive assembly applications, including pedal systems, electronic fuel injection, alternator assemblies, and LED headlamp controllers. These adhesives also provide corrosion protection and crash safety, aligning with strict regulatory mandates aimed at lowering the environmental impact of vehicles.

Construction and Aerospace

The construction sector benefits from moisture-curing adhesives widely used in roofing, insulation, and wood bonding applications due to their excellent resistance to external factors like moisture and temperature variations. Additionally, aerospace and defense industries are expanding the use of curing adhesives to contribute to lightweight and high-performance components critical for aircraft and defense equipment, further expanding demand.

Regional Market Landscape

Asia-Pacific dominates the global curing adhesives market, accounting for the largest revenue share and projected to grow at a CAGR of 8.33%. This growth is largely attributable to the region’s rapid industrialization, flourishing electronics manufacturing, and robust construction activities, particularly in countries like China and India. Technological innovation and increasing manufacturing capacities in Taiwan, South Korea, and Japan are also significant contributors.

Europe, noted for the presence of automotive giants such as Volkswagen, Mercedes-Benz, BMW, and FIAT, is expected to be the fastest-growing regional market after Asia-Pacific, with a CAGR of 7.67%. Moreover, Europe’s stringent environmental regulations, especially concerning VOC emissions, are motivating the adoption of advanced curing adhesives that are safer and more environmentally friendly.

North America remains a key player with a substantial market share, fueled by advanced plastics and automotive manufacturing sectors and the expansion of semiconductor chip production. The region’s regulatory focus on sustainability and innovation further drives demand. Latin America and the Middle East & Africa are witnessing growing adoption due to expanding manufacturing industries and investments in infrastructure development.

Types of Curing Adhesives and Their Applications

Acrylate Adhesives

Acrylate curing adhesives dominate the market segment, exhibiting a high CAGR of 8.23%. Known for their resistance to ultraviolet radiation, ozone, and moisture, acrylate adhesives are highly sought after in outdoor applications such as electrical insulation, solar panel production, automotive assembly, and furniture manufacturing.

Polyurethane Adhesives

Polyurethane adhesives stand out for their versatility, broad temperature resistance, and ability to cure in varied environments. Predominantly used to bond dissimilar materials like glass, aluminum, and fiber-reinforced plastics, they find extensive applications in the automotive and construction industries. Available in single-component moisture cure and heat cure formats, polyurethane adhesives offer flexible bonding solutions tailored to diverse manufacturing needs.

UV Cure Adhesives

UV curing adhesives cure rapidly upon exposure to ultraviolet light, providing strong, transparent bonds. Their superior precision and speed make them ideal for bonding metals, glass, ceramics, plastics, and rubbers in consumer goods manufacturing. The electronics sector especially benefits from UV curing technologies for surface mount device assembly and encapsulation due to reduced cycle times and enhanced product quality.

Moisture-Cure Adhesives

Moisture-cure adhesives react quickly to ambient humidity to form durable bonds, making them indispensable in construction where they are used for roofing, insulation, and bonding of various substrates. Their efficacy across metals, wood, and plastics ensures broad compatibility and high performance in demanding environments.

Challenges and Future Outlook

Despite significant growth prospects, the curing adhesives market faces challenges such as fluctuating raw material costs and supply chain disruptions. Environmental regulations, particularly regarding volatile organic compounds (VOCs), impose constraints on formulations, pushing manufacturers toward greener, low-emission products.

Looking ahead, technological innovations like digitalization, automation, and novel adhesive chemistries promise enhanced performance and expanded applications. Growing government investments in infrastructure, automotive lightweighting, and electronics will continue to drive demand. The convergence of sustainability with performance requirements will encourage the development of bio-based adhesives and recyclable solutions.

Conclusion

The curing adhesives market is poised for substantial growth fueled by its advantages in modern manufacturing, including strong, flexible bonds, resistance to harsh conditions, and eco-compliance. With broad applications spanning electronics, automotive, construction, and aerospace, curing adhesives are indispensable to industries aiming to balance performance with sustainability. Companies that innovate responsibly and adopt emerging technologies will lead this expanding market, powering industries with advanced bonding solutions into the future.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness