Synthetic Graphite Market: Powering the Future of Energy and Industry

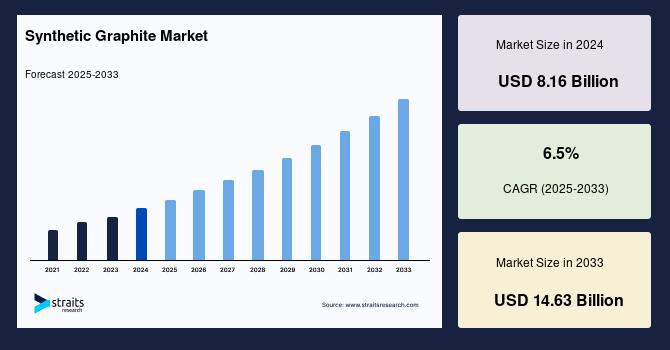

The global synthetic graphite market size was valued at USD 8.16 billion in 2024 and is projected to grow from USD 8.71 billion in 2025 to reach USD 14.63 billion by 2033, growing at a CAGR of 6.5% during the forecast period (2025-2033). Factors like high demand in the metallurgy segment drive the synthetic graphite market growth.

Overview of Synthetic Graphite and Its Production

Synthetic graphite is a high-purity form of carbon that is engineered by subjecting non-graphitic carbon materials such as petroleum coke and coal tar pitch to extremely high temperatures. This process transforms the raw materials into crystalline structures with exceptional electrical conductivity, thermal stability, and resistance to wear and thermal shock.

These properties position synthetic graphite as an indispensable material across diverse sectors, including energy storage, metallurgy, electronics, and industrial manufacturing. Unlike natural graphite, which can vary in quality and availability, synthetic graphite offers consistency and tailored properties essential for high-performance applications.

Driving Forces Behind Market Growth

The surge in electric vehicle production is a primary driver for the synthetic graphite market. EV batteries predominantly use graphite anodes, with synthetic graphite prized for its purity and performance. As governments worldwide implement stringent emission regulations and consumers shift towards sustainable transportation, demand for high-performance lithium-ion batteries continues to increase.

While natural graphite remains popular due to lower cost, battery manufacturers tend to blend it with synthetic graphite to optimize performance, cost, and environmental impact. Synthetic graphite enhances electrical conductivity and structural integrity within battery cells, contributing to longer cycle life and improved energy density.

Beyond batteries, the metallurgical industry is another significant growth contributor. Synthetic graphite electrodes are vital for electric arc furnace (EAF) steelmaking processes, where they conduct electricity to generate the intense heat required to melt scrap metal and raw materials. Rising crude steel and aluminum production globally has led to increased consumption of synthetic graphite electrodes, reinforcing demand in this sector.

Market Segmentation by Product Type

The synthetic graphite market comprises several product segments, each addressing specific industrial needs:

-

Graphite Anodes: The fastest-growing segment, centered around lithium-ion batteries for EVs and energy storage, with growth driven by increasing electric mobility and renewable energy deployment.

-

Graphite Electrodes: Crucial for steel and aluminum production via EAFs, these electrodes require high purity and robustness to withstand extreme operating conditions.

-

Graphite Blocks and Powders: Used in diverse industrial applications, including high-temperature reactors, electronics, solar panel manufacturing, and lubricants. These products benefit from synthetic graphite’s stability and conductivity.

Graphite anodes, in particular, are projected to grow rapidly as new battery technologies requiring ultra-pure and consistent graphite continue to develop. Advances in battery chemistry, including solid-state designs, are anticipated to further boost demand for premium synthetic graphite products.

Regional Market Dynamics

Asia-Pacific stands as the largest and fastest-growing market region, accounting for a significant share of global production and consumption. China, the region’s dominant player, not only leads in synthetic graphite manufacturing but also drives demand through its vast EV and solar power industries. Government policies promoting renewable energy, electric mobility, and industrial modernization fortify the region’s market position.

India is emerging as another key market within Asia-Pacific, propelled by initiatives such as the Faster Adoption and Manufacturing of Hybrid and Electric Vehicles (FAME) program, which supports EV adoption and the growth of battery manufacturing.

Europe holds a major market share as well, with Germany leading the region’s synthetic graphite demand, particularly linked to its automotive, steel, and renewable energy sectors. The continent’s push toward green steel production and clean energy technologies contributes to steady market expansion.

North America is witnessing marked growth stimulated by increased investments in domestic synthetic graphite plants and battery supply chains. Several large projects are underway to boost production capacities and reduce reliance on imports, motivated by the rapid growth of EVs and stringent environmental targets. The United States, Canada, and Mexico are key regional players, with expanding metallurgical and renewable energy industries adding to demand.

Challenges and Innovations

While synthetic graphite offers superior performance, its production is energy-intensive and costly compared to natural graphite. Balancing cost efficiency and sustainability is a persistent challenge for market participants. However, ongoing research and development activities focus on reducing carbon footprints by employing renewable energy in production, optimizing manufacturing processes, and developing new composite materials.

In addition, evolving battery chemistries and improving synthetic graphite characteristics such as particle uniformity and porosity control are enhancing battery performance, thereby opening new opportunities for innovation-driven growth.

Future Outlook

The synthetic graphite market is poised for sustained expansion as the global economy transitions towards electrification and decarbonization. With electric vehicles gaining market share and renewable energy systems requiring advanced energy storage, synthetic graphite will become increasingly valuable.

Emerging technologies such as fast-charging batteries, solid-state energy storage, and modular nuclear reactors present fresh avenues for synthetic graphite application. Additionally, increasing demand for green steel and aluminum production via EAF methods will further support the market.

Companies investing in scalable, environmentally friendly production technologies and strategic regional expansions are expected to lead the market. Collaboration between battery manufacturers, graphite suppliers, and automotive producers will be critical in meeting future demand and technological requirements.

Conclusion

Synthetic graphite stands at the crossroads of global industrial transformation, playing a pivotal role in shaping sustainable energy and manufacturing landscapes. Its unique material properties make it indispensable for a variety of high-growth sectors, notably electric vehicles and green metallurgy. As industries push towards cleaner, more efficient technologies, synthetic graphite’s market trajectory reflects both opportunity and innovation, underpinning the future of energy storage, mobility, and industrial production.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness