Industrial Robots: Pioneering Smarter Automation and Growth in 2025 and Beyond

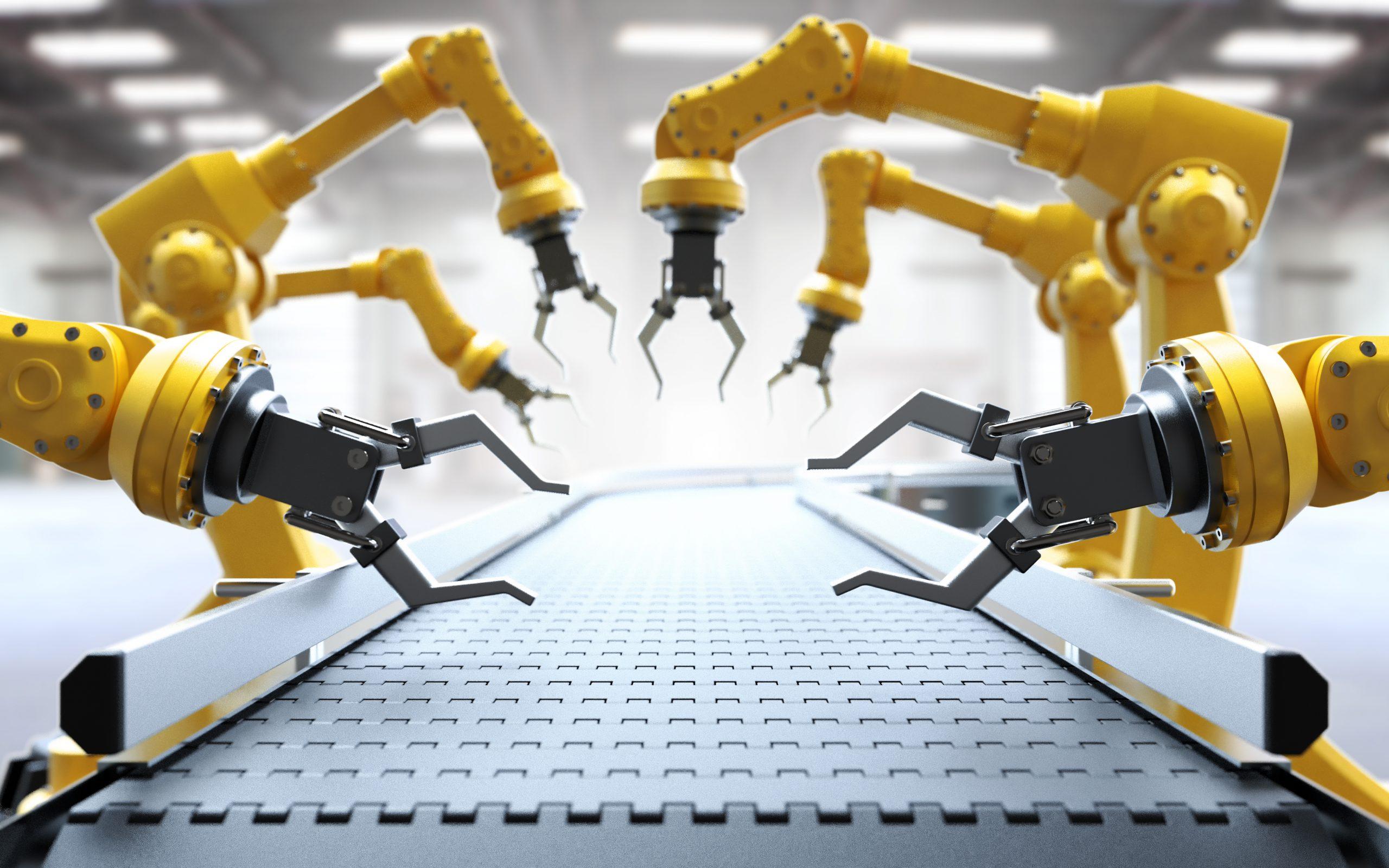

Industrial robots are transforming manufacturing and production landscapes globally, driven by advances in artificial intelligence (AI), machine learning, and collaborative robotics. Businesses are increasingly investing in robotics to enhance productivity, safety, and cost-efficiency in their operations. This accelerated adoption is fueling innovation across sectors, from automotive and electronics to logistics and pharmaceuticals, consolidating industrial robots as a cornerstone of Industry 4.0 transformations worldwide.

According to Straits Research, the global industrial robots market size was valued at USD 20.76 billion in 2024. It is projected to reach from USD 22.71 billion in 2025 to USD 46.61 billion by 2033, growing at a CAGR of 9.4% during the forecast period (2025–2033).

Recent Innovations and Industry News

2025 marks a milestone year for industrial robotics with breakthroughs in AI-enabled robots and expanded deployment of collaborative robots (cobots) that operate safely alongside human workers. Universal Robots, a Danish pioneer in cobots, launched its new generation of lightweight, easily deployable robots aimed at small and medium-sized enterprises (SMEs) that seek higher automation flexibility without complex programming.

Japanese leaders such as Fanuc, Yaskawa, and Kawasaki continue releasing advanced robots featuring enhanced vision systems and predictive maintenance capabilities powered by AI, optimizing factory uptime and product quality. Swiss-Swedish tech giant ABB introduced its next wave of robots incorporating energy-efficient designs and based on AI-driven adaptive algorithms enabling real-time task adjustments in automotive and electronics assembly lines.

Emerging manufacturers in China, including Siasun and Estun Robotics, are scaling production to meet surging domestic demand and expanding into global markets with cost-effective, versatile robots tailored for electronics manufacturing and logistics automation.

Leading Players and Regional Dynamics

Asia-Pacific

Asia-Pacific dominates the industrial robotics landscape with China, Japan, South Korea, and Taiwan as key hubs for R&D, production, and adoption. Japan’s Fanuc Corporation leads with sophisticated robots used across automotive and electronics sectors, while Kawasaki and Yaskawa supply globally renowned robotic arms with integrated machine vision. China increasingly invests in robotics as part of its “Made in China 2025” industrial upgrade, and South Korean companies like Hyundai Robotics push innovations in mobile robots and autonomous material handling.

Europe

Europe’s robot development is centered in Germany, Switzerland, Denmark, and Italy. German group KUKA GmbH remains a top European player focusing on AI-integrated robotics and digital twin technologies that enable virtual testing and optimization of automation workflows. ABB (Switzerland) is a leader in collaborative and industrial robot automation solutions emphasizing sustainability and flexible robotics for multiple industries. Denmark’s Universal Robots reigns in cobot development with a strong focus on accessible robotics for SMEs.

North America

The U.S. hosts several industrial robotic innovators, including companies like Boston Dynamics pioneering humanoid and mobile robots with advanced sensor suites and AI autonomy. Other key players include Teradyne, which owns Universal Robots, and Someci Robotics, focusing on specialized automation sectors. Investments by tech giants like Google and Amazon in robotics research further stimulate market growth.

Other Regions

India’s robotics adoption is growing rapidly, supported by government initiatives fostering automation in manufacturing and logistics. Latin America and Middle Eastern countries are gradually embracing robotics primarily in automotive and electronics manufacturing, often through partnerships with global companies.

Major Trends Shaping Growth

AI and machine learning integration enable robots to become more autonomous and adaptive, performing complex tasks with minimal human input. Vision-guided robotics enhance precision in quality control and assembly processes, while predictive maintenance reduces factory downtime.

Collaborative robots reduce the barrier to automation for smaller factories by safely working alongside humans without the need for extensive safety infrastructure. This trend democratizes automation and expands robotics beyond large corporations to SMEs globally.

Sustainability is another key driver, as companies adopt energy-efficient robots and optimize manufacturing workflows to reduce waste and environmental impact.

The rise of mobile and autonomous robots for logistics and warehouse operations is reshaping supply chains and e-commerce fulfillment centers, improving order accuracy and throughput.

Recent News Highlights

-

July 2025: Universal Robots unveiled its newest cobot generation at FABTECH Chicago, emphasizing ease of use for SMEs.

-

July 2025: ABB announced AI-driven adaptive robot lines for automotive manufacturing, boosting productivity and energy savings.

-

June 2025: Fanuc Corporation launched robots featuring enhanced vision and data analytics for electronics assembly lines.

-

July 2025: Dexterity Robotics initiated validation of its “superhumanoid” robot for logistics applications with Sagawa Express in Japan.

Outlook

The industrial robotics sector is poised for robust growth, uniquely positioned to address labor shortages, increase manufacturing flexibility, and boost global competitiveness. Investments in AI, autonomy, and service robotics will further enhance capabilities, making intelligent, collaborative, and mobile robots central to future factories and supply chains.

Summary

Industrial robots are rapidly revolutionizing manufacturing with AI-powered intelligence, collaborative working, and mobile automation solutions. Leading global players from Asia-Pacific, Europe, and North America are fueling innovation and growth with advanced robotics technologies. The continued expansion of robotics adoption will enable smarter, safer, and more efficient industrial operations worldwide.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness