CNC Cutting Machines Market: Revolutionizing Precision Manufacturing and Industrial Efficiency

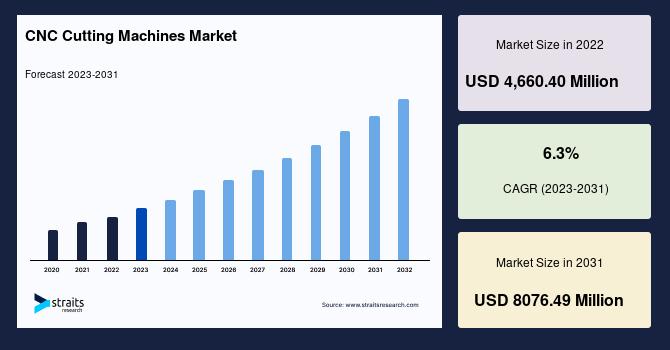

The global CNC cutting machines market size was valued at USD 4,660.40 million in 2022. It is projected to reach USD 8,076.49 million by 2031, growing at a CAGR of 6.3% during the forecast period (2023-2031).

Market Overview and Technological Advancements

CNC cutting machines are computer-controlled devices designed to cut, engrave, or etch complex components with high accuracy and speed using CAD (Computer-Aided Design) software. These machines outperform manual fabrication methods by offering unmatched precision, productivity, and operational efficiency. Types of CNC cutting machines include routers, laser cutters, plasma cutters, and waterjet systems, each optimized for specific materials and applications. These machines can process diverse substrates, including metal, plastic, glass, leather, and stone, making them versatile across a wide manufacturing spectrum.

The industry’s transition towards digitization, automation, and advanced manufacturing techniques has led to the proliferation of CNC technologies. Modern CNC machines integrate CAD/CAM software, robotic automation, and IoT-enabled monitoring, facilitating real-time adjustments, predictive maintenance, and streamlined production workflows. This progression not only improves output quality but also reduces waste and labor costs, delivering a higher return on investment for manufacturers.

Industry Applications and Key Drivers

Automotive Sector Dominance

The automotive manufacturing industry is the largest end-user of CNC cutting machines. Growing demand for vehicles and innovations such as electrification, autonomous driving, and connectivity require ultra-precise components and efficient production lines. CNC machines assist manufacturers in fabricating engine parts, chassis components, and intricate assemblies with minimal margin for error, helping meet stringent safety and quality standards.

The rise of electric vehicles (EVs) also contributes to market growth, as EV manufacturing necessitates specialized lightweight components and battery systems requiring precise CNC machining. Furthermore, automotive suppliers are leveraging CNC technology to reduce lead times and enhance customization capabilities, responding promptly to shifting market demands.

Aerospace, Electronics, and Construction

The aerospace sector’s need for high-tolerance, durable parts made from exotic materials like titanium and composites has accelerated CNC adoption. CNC machines enable the precision milling, drilling, and shaping required for aircraft components, ensuring compliance with rigorous regulatory standards.

In electronics and semiconductor manufacturing, CNC cutting machines produce miniature, complex parts necessary for devices such as smartphones and microchips. The evolving technology-driven consumer ecosystem demands rapid prototyping and consistent quality, both supported by CNC systems.

The construction and furniture industries are increasingly incorporating CNC routers and cutting machines for fabricating customized wood, metal, and stone components. Architectural designs benefit from CNC machines’ ability to produce complex patterns, engraving, and precise cuts, enhancing both aesthetic appeal and structural integrity.

Regional Market Insights

Asia-Pacific leads the global CNC cutting machines market, propelled by rapid industrial expansion in manufacturing hubs such as China, India, and Japan. The region’s extensive automotive, electronics, and consumer goods industries fuel strong demand for CNC technology. Additionally, growing government initiatives to promote digitization and industrial automation contribute to market growth, with Asia-Pacific expected to expand at a CAGR exceeding 7%.

Europe represents the fastest-growing market in some CNC segments, driven by technological innovation, robust automotive production, and extensive R&D investment. Prominent manufacturers in Germany, Sweden, and other countries consistently upgrade facilities with CNC systems, supporting high-value production and sustainable manufacturing goals.

North America maintains a significant market presence, with strong adoption in aerospace, automotive, and healthcare industries. The region’s focus on smart manufacturing, automation, and labor cost optimization underpins CNC machine integration. Emerging markets in Latin America, the Middle East, and Africa are witnessing rising demand driven by infrastructure development and expanding manufacturing capacity.

Market Segmentation and Trends

Type and Product Variations

CNC machines are typically classified into stationary gantry and moving gantry types. Stationary gantry systems, featuring fixed beams with moving tables, dominate due to enhanced stiffness and precision, especially suitable for small to medium-scale manufacturing. Moving gantry models, characterized by a travelling beam and fixed table, offer advantages in footprint and handling larger sheets, particularly for wood and softer materials.

By product, CNC routers hold the largest market share, attributed to their wide application in woodworking, automotive, and plastic industries. Laser cutting machines offer superior precision and are preferred in sheet metal processing and microfabrication. Plasma cutters are widely used for cutting thick metals in sectors like shipbuilding and heavy equipment, while waterjet cutters are valued for their ability to process delicate materials without heat damage.

Application Sectors

Metalworking dominates the CNC cutting machines market, accounting for the highest share. This application is critical in automotive, aerospace, electronics, and manufacturing sectors, where precision metal parts are integral. Woodworking follows closely, supported by growing demand for custom furniture, cabinetry, and architectural products. Stone cutting represents a niche but important market segment, driven by construction and artistic applications.

End-Use Industry Insights

The automotive industry remains the predominant end-user, with increasing CNC adoption driven by demand for complex, lightweight, and high-quality vehicle components. Building and construction are noteworthy contributors, where CNC routers produce components like decorative panels, flooring, and prefabricated modules. The furniture sector benefits from CNC technology by enabling flexible, fast, and accurate production of intricate designs.

Other key end-users include aerospace and defense, consumer electronics, medical device manufacturing, energy and power sectors, and transportation industries. These markets demand high-precision parts, often fabricated from advanced materials, fueling CNC machine innovation and customization.

Challenges and Future Outlook

Despite strong growth prospects, the CNC cutting machines market faces challenges such as skilled labor shortages, high initial capital expenditure, and maintenance requirements. The shortage of trained CNC programmers and operators can slow adoption, especially in developing regions. To address these bottlenecks, companies are investing in training, intuitive software interfaces, and automation features.

Looking ahead, technological advancements in AI-driven CNC operation, additive manufacturing integration, and Industry 4.0 connectivity are expected to redefine capabilities and applications. The rising emphasis on sustainability, waste reduction, and energy efficiency will push manufacturers to optimize CNC operations and explore eco-friendly materials.

In conclusion, the CNC cutting machines market is poised for continued expansion driven by multifaceted industry demand and technological progress. By enabling high-precision, scalable, and adaptable manufacturing solutions, CNC systems play a pivotal role in modernizing production, enhancing product quality, and supporting global industrial growth for years to come.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness